Retailing is the art of managing physical goods.

And, a retailer is like a juggler with multiple talents. She has to know about pricing, her customers' preferences, and the marketing techniques to attract those customers.

But more importantly, a retailer cannot exist without her stock. Good inventory management is one of the most important things that makes a retailer stand out from her competitors or make her fail in the long run. That's why mastering the art of inventory count is one of the most basic but the most important stand-out points for the retail business owner.

Even though the physical inventory count may seem like the simplest of all things, with a few practical tactics, the retailer can differentiate from her competitors and find an organized solution without investing a lot in technology.

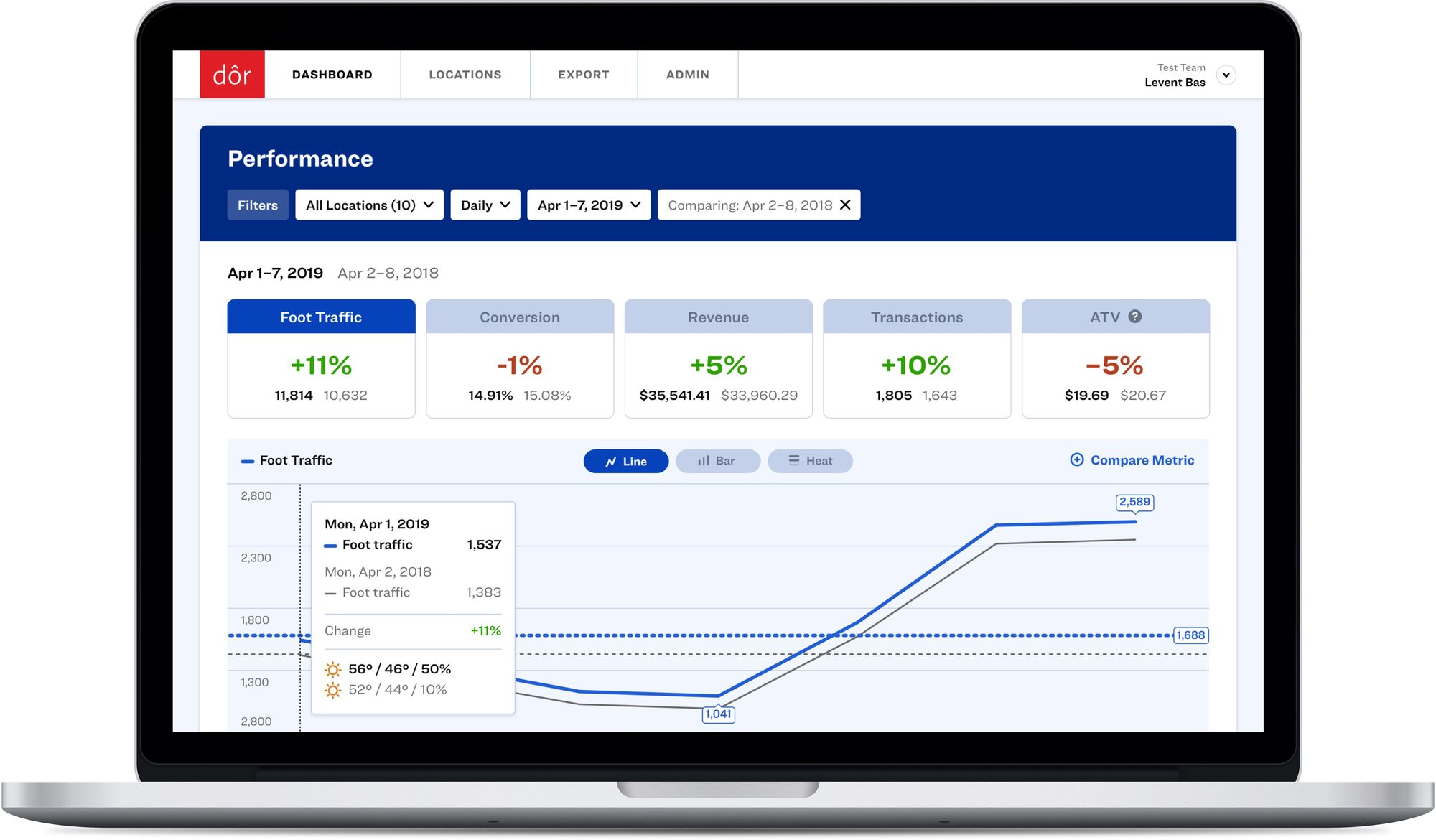

Did you know that a 1% increase in your store’s conversion rate can mean a 10% increase in revenue?

Click here to discover how Dor can help you understand your foot traffic data and make more profitable business decisions.

Ready to purchase? Complete your purchase in just minutes!

What is a physical inventory count?

A physical inventory count is how a retailer knows the amount of inventory she has in her sales floor, stockroom, or warehouse if she operates in one. Even though it sounds simple, the beginning list minus net sales, with everything going on in a chaotic retail store every day, the ends may not meet the odds at the end of the day.

That’s why in addition to the financial calculations that help you manage your inventory, the periodic physical count of inventory is necessary to make them meet.

The physical inventory count is a simple process. However, it takes time and needs focus, so usually, it's conducted by the retailer herself with a few staff members. The straightforward way to do a physical inventory count is using a manual recording or maybe an organized spreadsheet, but retail technology offers not-so-complicated solutions.

Benefits of doing a physical inventory count

Making sure you have enough products to sell

Even if you work with a good inventory management system, you are actually selling physical products and not data in your inventory reporting tool. Physical inventory count allows you to make sure your data matches your potential sales, so you won't be miscalculating when you work on your prospective sales target.

Related: Excess Inventory: How to Liquidate Old and Surplus Stock in Retail

Keeping the stockroom tidy

The physical process of counting inventory helps you organize your stock room more frequently. Before you begin the stocktake, the retailers usually divide the stock room or the sales floor to guide the counters. This division and the thought behind how quicker the rooms can be organized will lead to increased tidiness. You’ll see all the unnecessary items piled up behind the store, and it will give you a chance to remove them before it gets into chaos.

Related: 8 Tips to Organize Your Retail Stockroom to Increase Efficiency

Theft prevention

Worst things worse, even though you keep your store as secure as you’d want, theft is more common than imagined. Whether it's an external or internal mugging, sometimes it’s conducted so professionally that you may not even realize that you lose a toll of money in the long run.

Customer satisfaction

Retail business is designed to improve customer satisfaction. Customers are not just the ones who are in your store physically. Still, they are the people who call you to ask whether you have a product in-store so they can come by to pick it up, or maybe you have an online channel integrated into your physical store.

Hence, they buy without even consulting product availability with you. If you have multiple retail channels such as phone or online, product accuracy is twice as important. These customers rely on your data to either drive by your store or order online, and they are more frustrated when you tell them that you had to cancel their order because you don't have that product in your physical inventory even though your data claims there is.

Important things to focus on when counting inventory

Who has access to the inventory?

Before you begin counting physical inventory, think about who has access to inventory and who will be responsible for counting it.

Knowing who had access to your inventory beforehand will make it easier to solve issues if there is any inaccurate inventory. It may be you or your trusted staff who do the inventory counting, but in case you need a more objective count, you may consider working with a third-party vendor as well.

Your accounting accuracy

Most of your inventory numbers are stored in your accounting system. Ensure this system is well integrated with your inventory management system so that it will turn out the same results when you do the physical count.

If there is a fault in the accounting system, this is the head start for improving your business.

Cut off times

When you do the inventory count is also important for accuracy. Most of the accounting for inventory management programs change inventory levels as they are invoiced. So, if your program invoices overnight, it may be best to do the inventory count in the morning before the store opens to avoid misleading.

Best practices for physical inventory counting

- For many retailers, the physical count is planned ahead, and it usually occurs once or twice a year, especially when the financial year is closing to get ready for a fresh start. However, each retailer has her own scheme, so the frequency of your physical inventory count should be determined by why you need to do it in the first place. You may choose to count your inventory twice a year, July and January in some cases, or do a weekly count each Monday morning, depending on your business requirements.

- Even though physical inventory count can be done with a pen and paper, basic to advanced technology can be time-saving.

- Excel/Spreadsheets: Using good old Microsoft Excel or Google Spreadsheet is effortless, and with their mobile applications, you can walk around your stockroom and type as you count. Keep in mind that this method only works if you have a limited number of SKUs, as the more rows you have on your spreadsheet, the harder it will be to manage the system.

- Scanners: You can use hand-held barcode scanners to scan the barcodes of your inventory; these devices may connect to your inventory management system or your accounting records to transfer data immediately.

- Scanner apps: An alternative to barcode scanners is barcode scanning apps. If you prefer to work with these apps, no additional physical good purchasing will be required, so it's more cost-effective and productive at the same time.

- Internal preparation is the key to an effective physical stock count. Make sure that you work with your staff to prepare to know when to begin and where to start. You’ll have to arrange their overtime if you need to, make sure they have enough food and water to support them during this long process. Counting inventory is a repetitive process that involves a lot of concentration which may lead to fatigue. Arrange break times for you or your staff so everyone has a clear mind and you don't have to repeat the process all over again.

- Absolutely no one but the responsible staff should be in the stockroom or the sales floor during these hours. Imagine everything stops for a few hours, and then your business life resumes after this. This is an easy-looking task that will positively impact the business in the long run. So make sure you pay enough attention to every little detail.